EPD co-deposition of Ceramic protective coatings for solid oxide cells interconnects

Description: Ceramic-based coatings are currently used to protect metallic interconnects for SOCs, in order to limit chromium poisoning of the oxygen electrode. Enhanced efficiency and durable electrochemical energy conversion can be achieved only by suitable material choice with proper functional requirements. Mn-Co based spinels have been suggested as the best candidates for protective materials for steel interconnects of Solid Oxide Cells.

Electrophoretic deposition (EPD) is a synthesis process that allows to produce coatings with controlled thickness, morphology, density and composition. It involves the movement and the deposition of charged particles suspended in a liquid solution when an electric field is applied between two or more electrodes.

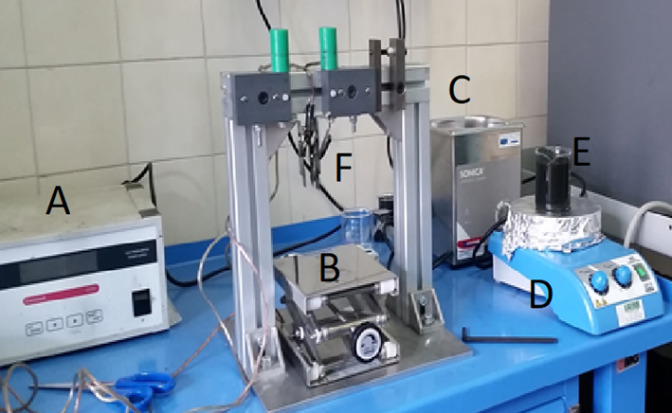

Figure 1: Set-up used for the EPD @ POLITO-GLANCE:

A) Power supplier, B) Holder, C) Ultrasonic bath, D) Magnetic stirrer, E) Becher, F) Counter electrodes.

A novel prospective offered by the EPD technique is the possibility to achieve Cu or Fe-doped Mn-Co spinel coatings by a single-step co-deposition of different oxides. This “in-situ” approach allows to reduce the processing time and cost.

Figure 2: Schematic diagram showing the electrophoretic deposition process of manganese-cobalt spinel-based coatings. A) ex-situ doped spinel; B) in-situ copper doping; C) in-situ iron doping [E. Zanchi et al, Recent advances on spinel-based protective coatings for solid oxide cell metallic interconnects produced by electrophoretic deposition, Mater. Lett. 286 (2021) 129229]

Coatings obtained by electrophoretic co-deposition have already demonstrated high stability during long-term tests at the SOCF operating conditions, efficiently reducing both the corrosion of the metallic interconnect and the Cr evaporation.

Figure 3: Cross section EDX mapping of Fe-doped Mn-Co spinel after 2000 h at 750°C and EDX semi-quantitative results in at. % collected on the marked region

Keywords solid oxide cells, coating, EPD, ceramics for energy

Contacts: Federico Smeacetto federico.smeacetto@polito.it, Elisa Zanchi elisa.zanchi@polito.it

Recent reference(s)s

- Elisa Zanchi, Antonio Sabato, Sebastian Molin, Grzegorz Cempura, Aldo R. Boccaccini, Federico Smeacetto (2021). Recent advances on spinel-based protective coatings for solid oxide cell metallic interconnects produced by electrophoretic deposition. MATERIALS LETTERS, vol. 286, p. 129229, ISSN: 0167577X, doi: 10.1016/j.matlet.2020.129229.

- Elisa Zanchi, Sebastian Molin, Antonio Sabato, Belma Talic, Grzegorz Cempura, Aldo R. Boccaccini, Federico Smeacetto (2020). Iron doped manganese cobaltite spinel coatings produced by electrophoretic co-deposition on interconnects for solid oxide cells: Microstructural and electrical characterization. Journal of Power Sources, vol. 455, p. 227910, ISSN: 03787753, doi: 10.1016/j.jpowsour.2020.227910

- Elisa Zanchi, Belma Talic, Antonio Sabato, Sebastian Molin, Aldo R. Boccaccini, Federico Smeacetto (2019). Electrophoretic co-deposition of Fe2O3and Mn1.5Co1.5O4: Processing and oxidation performance of Fe-doped Mn-Co coatings for solid oxide cell interconnects. Journal of the European Ceramic Society, ISSN: 09552219, doi: 10.1016/j.jeurceramsoc.2019.05.024

- Sebastian Molin, Antonio Gianfranco Sabato, Hassan Javed, Grzegorz Cempura, Aldo R. Boccaccini, Federico Smeacetto (2018). Co-deposition of CuO and Mn1.5Co1.5O4 powders on Crofer22APU by electrophoretic method: Structural, compositional modifications and corrosion properties. MATERIALS LETTERS, vol. 218, p. 329-333, ISSN: 0167-577X, doi: 10.1016/j.matlet.2018.02.037

- Antonio Sabato, Sebastian Molin, Hassan Javed, Elisa Zanchi, Aldo R. Boccaccini, Federico Smeacetto (2019). In-situ Cu-doped MnCo-spinel coatings for solid oxide cell interconnects processed by electrophoretic deposition. Ceramic Internationals-accepted for publication

Funding Projects

NewSOC - Next Generation Solid Oxide Fuel Cell and Electrolysis Technology - H2020-JTI-FCH-2019-1; GA 874577

ESTEEM3 - Project title: Advanced glass and ceramic materials for energy applications; Project acronym: GlaMater. Commissioned by European Union’s Horizon 2020 research and innovation programme under grant agreement No 823717

GrInHy- Green Industrial Hydrogen via reversible high-temperature electrolysis-H2020-JTI-FCH-2015-1; GA 700300

CoACH- Advanced glasses, Composites and Ceramics for High growth Industries ETN Marie Skłodowska-Curie GA 642557

Collaborations:

Prof. Aldo R. Boccaccini, Department of Materials Science and Engineering, University of Erlangen-Nuremberg - FAU, Erlangen, Germany

Prof. Sebastian Molin, Faculty of Electronics, Telecommunications and Informatics, Gdańsk University of Technology, Gdańsk, Poland

Prof. Albert Taracón, Catalonia Institute for Energy Research - IREC, Barcelona, Spain

Dr. Christian Walter, Sunfire GmbH, Dresden, Germany

Dr. Hassan Javed, Sunfire GmbH, Dresden, Germany

Dr. G. Cempura, AGH University of Science and Technology, Krakow, Poland

Dr. Antonio Sabato, Catalonia Institute for Energy Research - IREC, Barcelona, Spain